Olive oil producers

for generations

Our work has been handed down since 1867.

The Frantoio Bo was born in the rural context of a Ligurian seaside village.

To date, it serves more than 1,500 olive growers in the area and ranks among the best Ligurian producers. In recent years, we have received numerous awards, including at the international level.

We have a deep-rooted dedication

for our craftsmanship

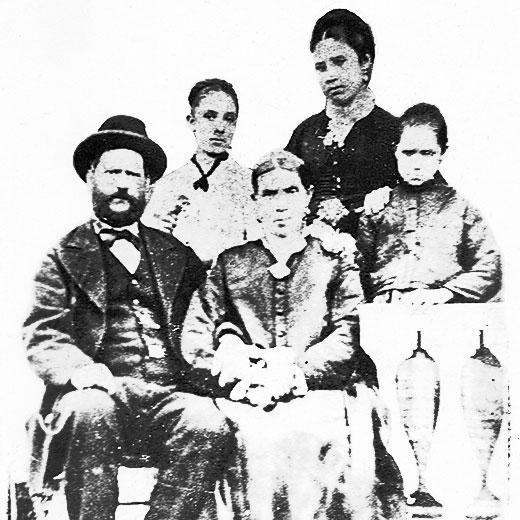

Ours is a tradition that has its roots in very remote times. A few years ago, my father Carlo researched the origins of our family and identified who among our ancestors started the olive milling activity.

The research allowed him to go back to the mid-nineteenth century, but we cannot exclude that our ancestors had owned an olive mill long before then.

It all started when Bo Giuseppe, in 1867, bought from a nobleman at auction the existing property where an olive oil mill was already present. Its sandstone base and screw of the press are still preserved.

The mill was for family use and for farmers in the immediate area surrounding the property. It was operated exclusively by animal force.

1867

2020

Giuseppe’s son Marco (my great grandfather) followed in his father’s footsteps, but died young. Despite the premature death of his father, his son Domenico was fascinated by the art of becoming an oil producer and decided to upgrade the mill based on new technologies. This is when the mill was converted into one of the first electrically operated mills in the region.

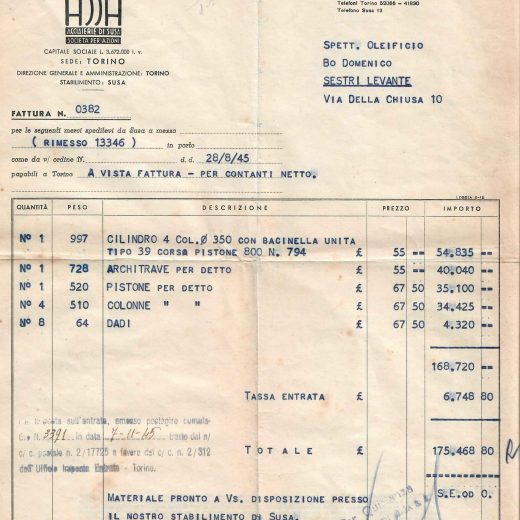

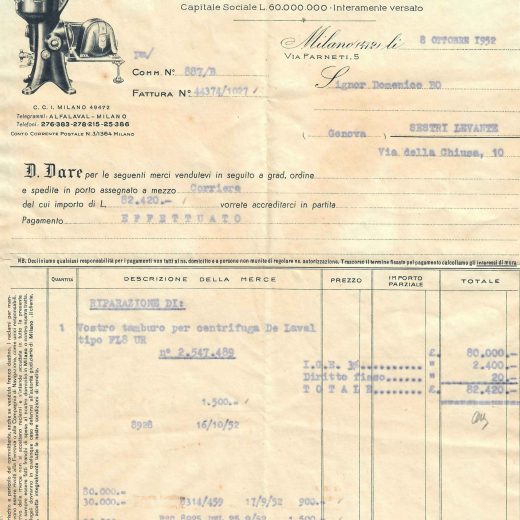

The plant remained in operation until 1958. It was composed of electrically powered millstones, two “foratina” presses and a De Laval centrifuge to separate the oil from vegetation waters.

1945 the purchase of the first presses

1952 revision of the first DeLaval separator

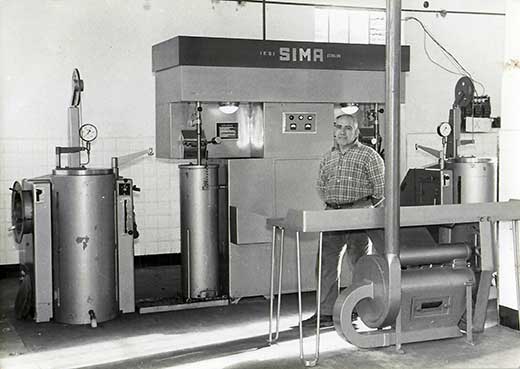

1958 the "Baglioni'' plant of my grandfather Domenico

In the following years, the plant was further upgraded with the introduction of a mechanical crusher that is part of the “Baglioni patent” and two presses purchased from the Sima-Oma company. The olive kernel, once separated from the pulp, was used as a draining surface.

This plant remained in operation until 1976, when my father Carlo decided to modernize it.

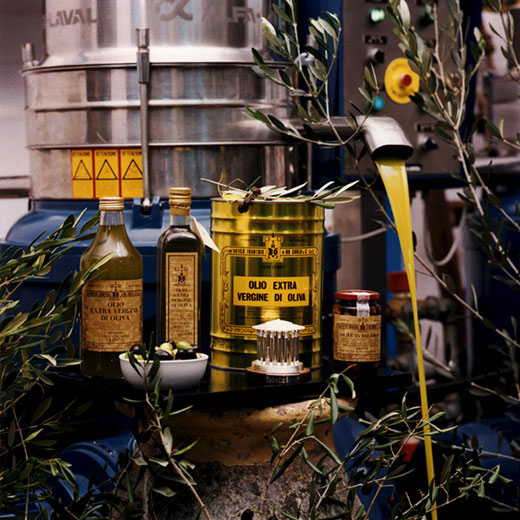

This is when the Frantoio Bo equipped itself with one of the first Alfa Laval systems, consisting of a mechanical crusher, three kneaders, a 3-phase decanter and two centrifugal separators (one for vegetation waters and the other for olive oil).

In 1998, following the growing business demands, the 800kg / hour decanter was replaced with a more powerful and modern machine with a transformation capacity of 2000kg / hour. The crusher was also replaced to ensure the right supply of olive paste into the new machine.

1980 the first bottles

1980 our products

In 2009 the plant underwent a further modernization process that led to the replacement of the five kneaders arranged in a line with five parallel kneaders. This variation greatly accelerated the transit of the paste into the decanter without the need to wash all the tanks in which each batch of olives was passing through.

Shortly thereafter, we conceived, designed, and built a machine to process the olive pomace and separate the crushed stones from the pulp. The dry, crushed stones are now used as combustible material for the production of hot water necessary for the operation of the plant.

“Making an excellent extra virgin olive oil is simple: it requires perfect olives, an olive mill and one hundred and fifty years of experience.”

— CARLO BO

OUR OLIVE MILL

can be visited all year round. From October to January we are primarily engaged in the production. The following two months until around Easter are mostly dedicated to the meticulous cleaning, dismantling and maintenance of the machinery. The summer period is dedicated to direct sales and guided tours.

CONTATTI

Via della Chiusa 70

16039 Sestri Levante GE

Italia

Telefono: +39 0185 481605

Email: info@frantoio-bo.it